In industries such as Automotive, Packaging or Aerospace & Defense, we know full traceability in one seamlessly integrated system is key.

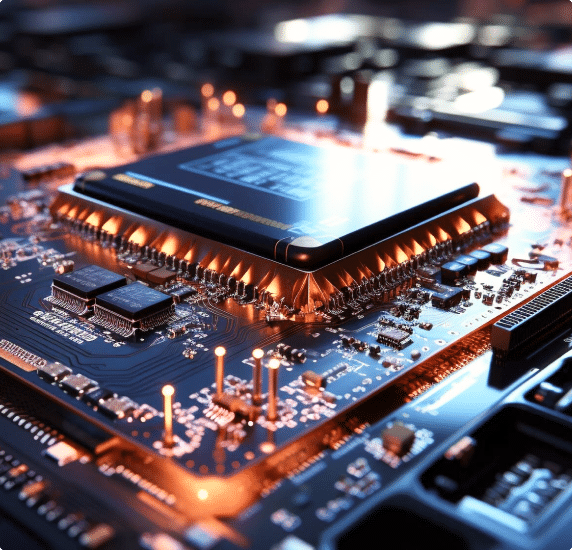

Manufacturing High Tech & Electronics requires adaptability to keep up with the evolving demands and trends, and to accommodate growth.

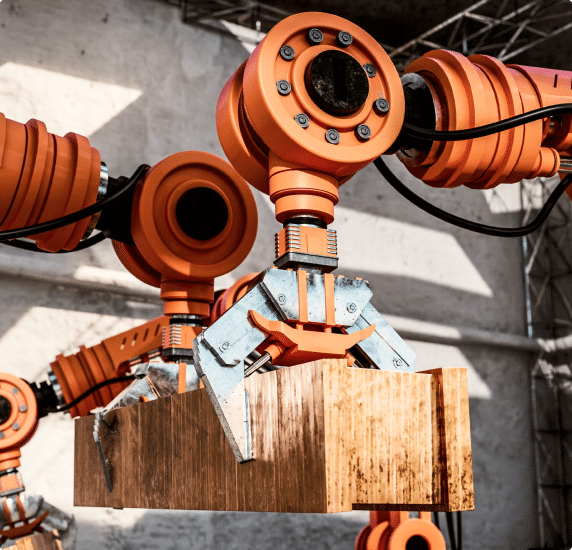

Small and medium-sized manufacturers of Industrial Machinery and so many other products need to, as suppliers, be ready to respond quickly and innovate.

In industries such as the Plastic Processing and the Metal Fabrication ones, it is essential to find ways of holding that competitive advantage within production processes and not just the product.